Mechanical Engineering

Comprehensive Program Features & Benefits

Machines rule the world today. They have become so indispensable a part of our lives, be it in home or in office, we simply take them for granted. From wrist watches to tower clocks, from toy cars to concords, from electric shavers to earth movers, from car jacks to derrick cranes, from coffee machines to concrete mixers, from simple motors to tunnel borers, and, as well, in almost endless list of applications their presence is pervasive and their use inevitable. The discipline of Mechanical Engineering encompasses all the theoretical input needed to design machines, from Principle of Lever to Theory of Machines, and all allied concepts and practice, from electricity and thermodynamics to welding and numerical controls, needed to design new machines.

Machines have become more sophisticated in features and appearance, absorbing every new discovery and technology in the discipline of mechanical engineering and allied fields. The Mechanical engineers have always faced interesting challenges to design new machines and devices to unique and emerging situations and have always come up with wonderful innovations like porklines and nanocars.

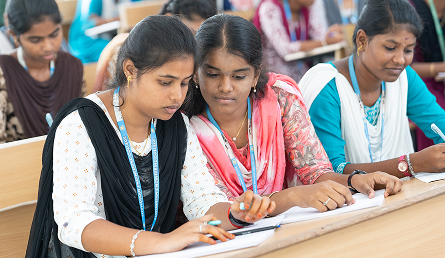

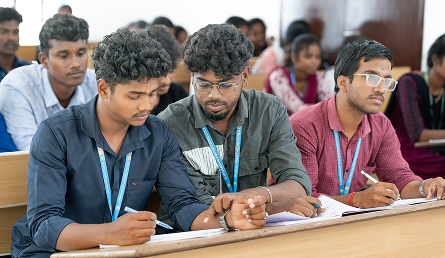

The Department of Mechanical Engineering in Sudharsan Engineering College teaches and trains its students to meet all kinds of field challenges with technical confidence. The department keeps acquiring latest machines and instruments every year to add to its already complete training stock in the workshops and laboratories. The faculty members are amply qualified and well-experienced in industry. They ensure that their students receive industrial relevant knowledge and training along with curricular fulfillment.